13 May ACCESSORIES: Doteco’s suction lances

In this post we are going to introduce suction lances, an accessory that can, along with the design of the conveying system, influence the performance of the materials loading.

CHOOSING THE RIGHT LANCE

Choosing the right suction lance is one of the key factors to ensure the proper functioning of the material aspiration and conveying system. Using a non appropriate lance could slow down the loading process or even cause severe clogging, consequently leading to a performance and efficiency loss.

Doteco provides two type of lances: SINGLE or COAXIAL. They are the result of many years of experience and tests on the field, to ensure maximum reliability.

SINGLE LANCE

It is the most widely used type of lance, ideal for suctioning of materials with a bulk density up to 0,5-0,6 kg/l.

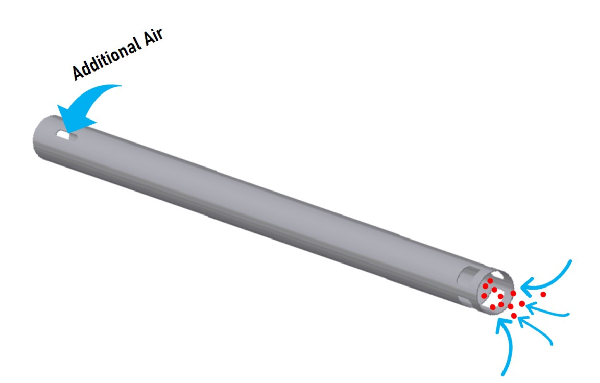

The design is very simple, focused on performance efficiency. Thanks to air inlets placed on the top, additional air can be conveyed within the suction hose, increasing the material flow fluidification.

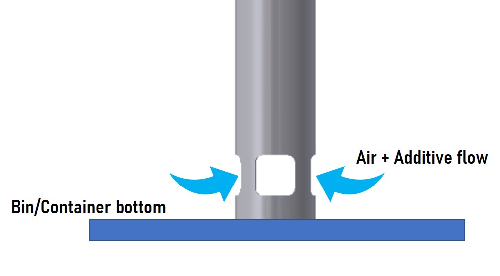

The openings placed on the distal end, avoid that the passage of material is obstructed by the bottom of the container/bag, in case the lance reaches it.

Pros and Features:

- It’s the simplest and most inexpensive solution.

- Lightweight and easy to handle.

- Additional air can be conveyed within the suction hose, thanks to eyelets placed on the upper part of the lance.

- The additional air flow can be adjusted by covering or uncovering the eyelets with the suction hose.

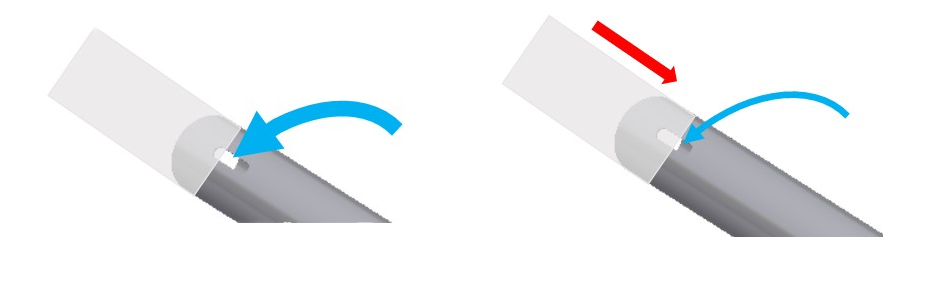

Additional air flow adjustment:

Depending on how the hose is positioned over the eyelet, it is possible to adjust the additional air flow.

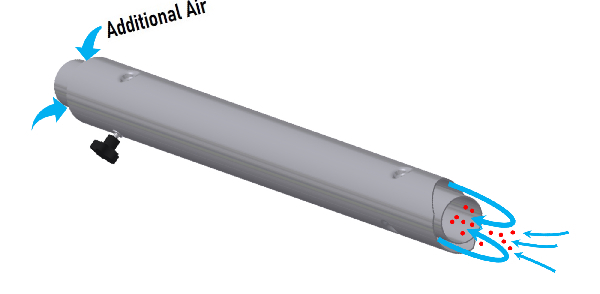

COAXIAL LANCES

Coaxial lances are indicated for materials with a bulk density from 0,8-1,0 kg/l and above, such as masterbatches or additives.

Thanks to the design, realized by utilizing two coaxial pipes, compared to a single lance, it is capable of suctioning a larger and always constant air quantity; additional air is collected from the upper part of the pipe and then conveyed towards the tip (bottom part), where it mixes with the material.

This system prevents clogging or slowing down of the material during the conveying process.

Unlike the single lance, additional air flow is act directly where the material is aspirated, dratically reducing the risk of clogging.

Pros and Features:

- Ideal for masterbatch and “heavy” additives (>0,8-1,0 kg/l).

- Thanks to its design, a considerable amount of additional air can be channelled to support the material suctioning.

- The air flow can be easly adjusted.

- Under some circumstances, increases the efficiency of the loading system (compared to the single lance).

Additional air flow adjustment:

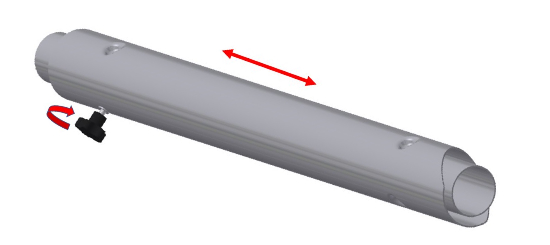

By untightening the ergonomic knob, the external coaxial pipe can slide, increasing or reducing the flow of additional air.