Ideal in case of:

– frequent lay-flat size changes (on-the-fly);

– low line speed;

– personnel with limited experience.

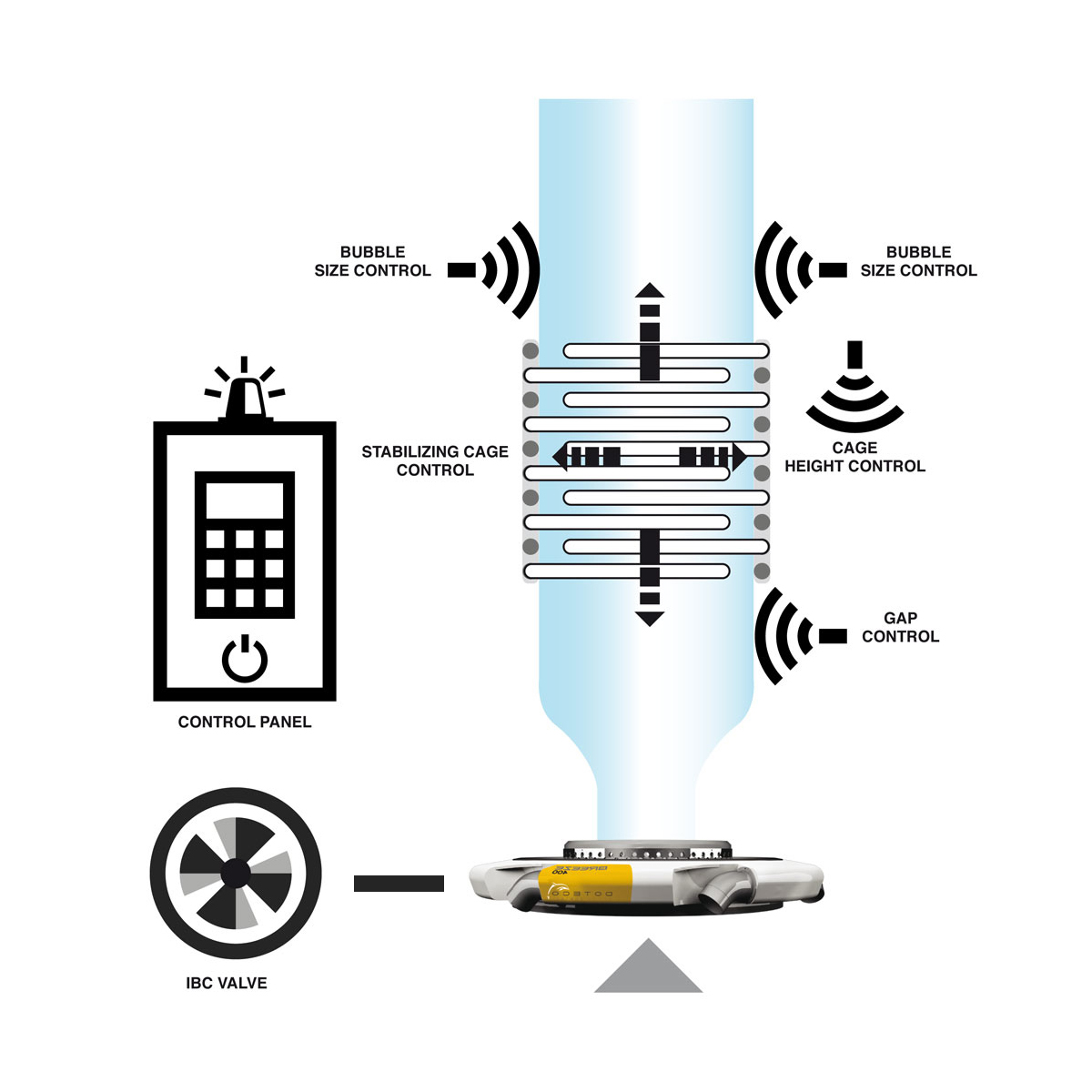

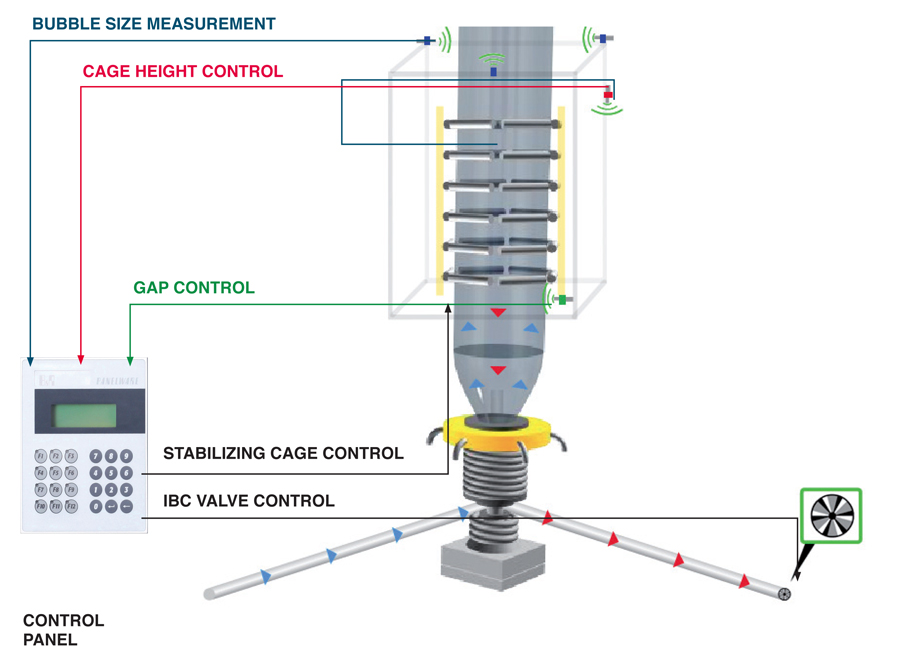

- Simple to use: just set the lay-flat set point andtolerance targets.

- Save time and reduce waste during start-up and size changes.

- Lower tolerances and much better control than with manual adjustments.

- Constant lay-flat stability, all through the production process.

- Supplies process information needed to validate the production lot as required by quality assurance.